I’m much happier when development boards are protected by some sort of basic enclosure. Even when they spend most of their time sitting on an anti-static mat on the workbench, with prolonged use there is still the worry that a cable may inadvertently get pulled and cause a board to short against another, tools or some other metallic object.

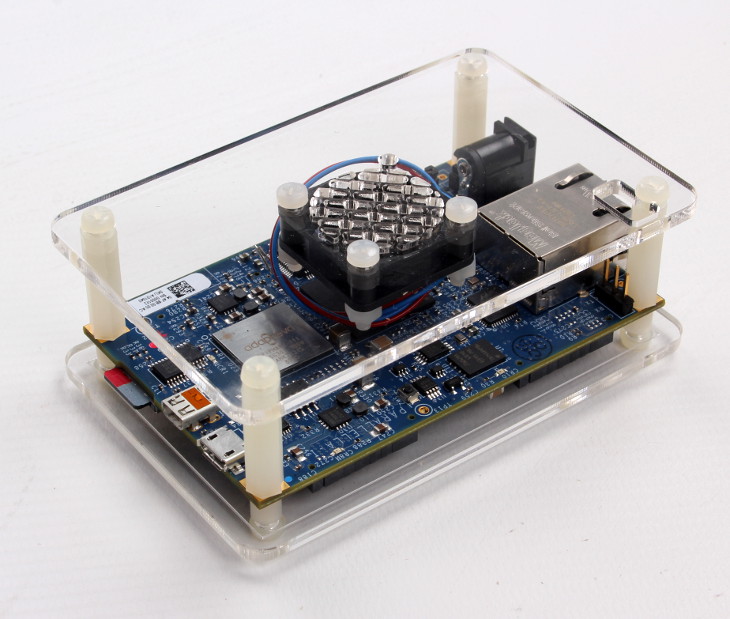

A fully enclosed case is not necessary for hardware development hardware and a simple, elegant solution is to simply mount the board to a base plate, with spacers and then a top plate. This allows for good ventilation and if clear acrylic is used you can easily check the status of LEDs.

With this in mind I decided I needed to get cases made for Parallella and UmTRX boards, and since I don’t presently have access to a laser cutter, I enlisted the help of Aaron at Oomlout — an advocate of subtractive manufacturing who has a great many tube hours racked up.

Parallella

The Parallella may only dissipate around 5 watts under typical loads, but it is a compact and densely populated board and when housed in enclosure use with a fan is strongly recommended. The Zynq, with its dual ARM cores and programmable logic, dissipates the majority of the power consumed and this should have a heatsink attached.

Access to the UART header is possible through a small hole in the top plate.

The design files and BOM can be found in the parallella-open-case repository.

UmTRX

UmTRX dissipates somewhere in the order of 16 watts and the case for this was made to accommodate a slightly larger fan.

The SMA connectors at the front of the board are for the GPS antenna and clock and PPS signals. Each of the two transceiver channels has 3x UFL sockets, to which short cables are attached with SMA sockets at the other end. Aaron came up with a neat solution whereby the bulkhead mount sockets are fitted to panels which can be positioned anywhere along the sides of the enclosure, to give increased flexibility.

The design files and BOM can be found in the umtrx-open-case repository.

— Andrew